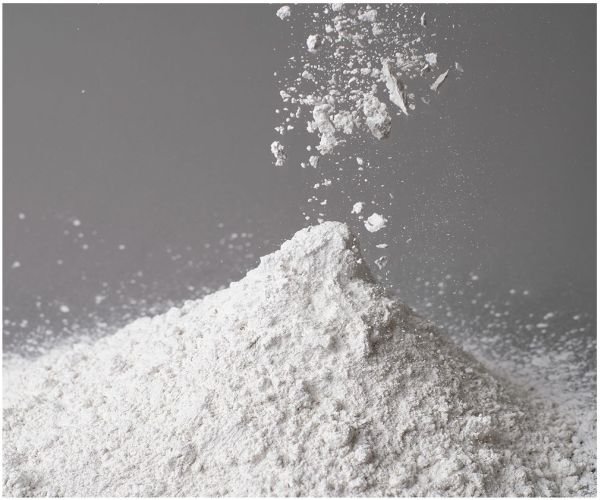

Handling quicklime powder, also known as calcium oxide (CaO), requires caution because it can be hazardous if not handled properly. Quicklime is highly alkaline and can react with water to produce intense heat. Here are some safety precautions to follow when working with quicklime powder:

- Personal Protective Equipment (PPE):

- Wear protective clothing, including long-sleeved shirts and long pants to minimize skin exposure.

- Use chemical-resistant gloves and safety goggles to protect your hands and eyes.

- Wear a dust mask or respirator with appropriate filters to prevent inhaling airborne particles.

- Ventilation:

- Work in a well-ventilated area to reduce exposure to airborne quicklime dust.

- Avoid Contact with Skin and Eyes:

- In case of contact with the skin, wash the affected area immediately with plenty of water and seek medical attention if irritation or burns occur.

- If quicklime comes into contact with your eyes, flush them with copious amounts of water for at least 15 minutes and seek immediate medical attention.

- Prevent Inhalation:

- Minimize the generation of dust by handling quicklime powder gently.

- If dust is produced, use a dust mask or respirator to prevent inhalation.

- Handling and Storage:

- Store quicklime in a dry area, away from moisture. Quicklime reacts with water, releasing heat, and forming slaked lime (calcium hydroxide).

- Keep containers tightly sealed to prevent moisture from entering.

- Use Dry Tools:

- Use dry tools and equipment when working with quicklime to prevent moisture from coming into contact with the powder.

- Emergency Measures:

- Have a supply of water nearby for emergency use, as water can be used to dilute and neutralize quicklime if an accident occurs.

- First Aid:

- Ensure that first aid supplies are readily available when working with quicklime.

- Training:

- Provide proper training to personnel handling quicklime to ensure they are aware of the hazards and safe handling procedures.

- Spill Response:

- In the event of a spill, contain the material and clean it up carefully. Avoid creating dust during cleanup, and use appropriate absorbents or neutralizing agents as needed.

- Disposal:

- Dispose of quicklime waste in accordance with local regulations and guidelines. It may be considered hazardous waste and should be treated and disposed of accordingly.

It’s essential to familiarize yourself with the Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) for the specific quicklime product you are using, as it provides detailed information on its hazards, safe handling, and emergency procedures. Always prioritize safety when working with potentially hazardous substances like quicklime.