Introduction

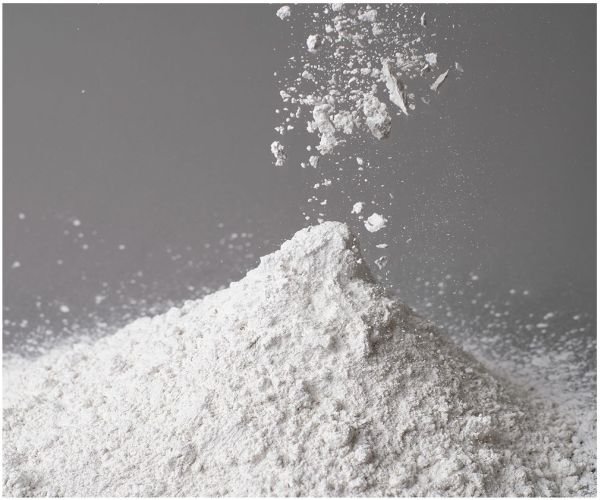

Hydrated lime is a commonly used additive in the steel industry. Hydrated lime, also known as calcium hydroxide or slaked lime, is a white powdery substance that is used to adjust the pH levels of a steel product or to provide an alkaline environment for the steel to react with other substances. It is also used as a coating on steel surfaces to prevent corrosion.

Chemical Properties

Hydrated lime is made of calcium oxide, also known as quicklime, and water. It has a pH of 12.4 and is a highly alkaline material. It is insoluble in water and is not combustible. The calcium hydroxide produced from hydrated lime reacts with carbon dioxide in the air to form calcium carbonate, which is much less soluble in water.

Uses in the Steel Industry

Hydrated lime is an essential product in the steel industry, as it serves a variety of purposes. It is primarily used to help reduce slag viscosity in the steelmaking process, to improve the efficiency of the process and to increase the quality of the finished steel product. Hydrated lime is also used to purify the steel by removing impurities, to reduce the acidity of the melt and to reduce the amount of carbon that is released into the atmosphere during the steelmaking process. In addition, hydrated lime can be used to reduce the amount of sulfur dioxide that is released into the atmosphere during the steelmaking process and to help reduce the amount of hazardous waste produced by the steel industry.

Benefits of Using Hydrated Lime in the Steel Industry

1. Improved Quality: Hydrated lime is often used to improve the quality of steel, as it helps to reduce the amount of residual elements and other impurities in the final product.

2. Enhanced Heat Resistance: Hydrated lime helps to increase the steel’s heat resistance, making it more durable and less likely to warp when subjected to extreme temperatures.

3. Reduced Costs: The use of hydrated lime in the steel industry can reduce costs by reducing the amount of energy needed to produce steel.

4. Improved Safety: Hydrated lime helps to reduce the amount of carbon monoxide produced during steel production, which can result in improved safety for workers and the environment.

5. Improved Strength: Hydrated lime can also help to improve the strength of the steel, allowing for a stronger and more durable final product.

Synergy Chemical Industries Manufacturer in India:

Synergy Chemical Industries is one of the leading manufacturer of hydrated lime in India. We offer a wide range of products and can customize our products according to your needs. Our experienced support team is always ready to help you with any queries or concerns you may have. Contact us today to know more about our products and how we can help you improve the quality of your steel products.

Conclusion

Hydrated lime is a commonly used additive in the steel industry. It is used as a fluxing agent, a protective coating, and to adjust the pH levels of steel products. It is a very cost-effective way to improve the corrosion resistance of steel products and can provide a number of other benefits as well.