Table of Content

- Introduction

- Why Limestone Quality Varies Widely in India

- Key Factors to Evaluate in Limestone Manufacturers

- Types of Limestone Available in India

- How to Choose the Best Limestone Manufacturer in India

- Limestone Price in India per Ton

- Benefits of Buying Limestone in Bulk

- Why Many Buyers Prefer Synergy Chemical Industries

- Common Mistakes Buyers Make While Ordering Limestone

- FAQs

Introduction

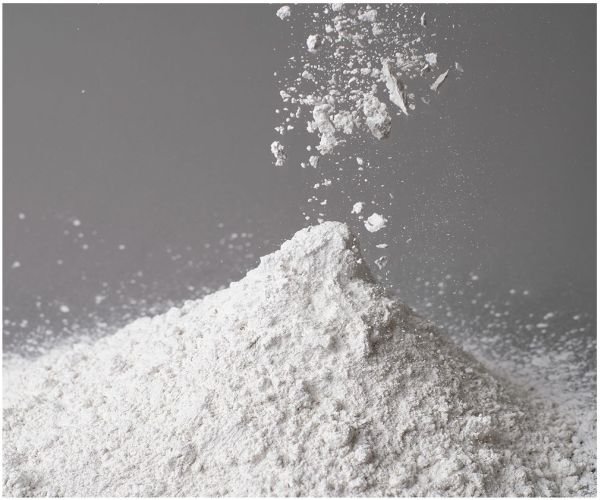

Choosing the right limestone manufacturers in India can feel confusing, especially when every supplier claims to offer “high-quality limestone”. But the reality is this: limestone quality, purity, and consistency vary greatly from one manufacturer to another. And for industries like construction, steel, chemicals, water treatment, and agriculture, the wrong limestone grade can cause production issues, structural weakness, and financial loss.

This blog is designed to guide you through the essentials before you place your order. You’ll learn what affects limestone quality, which checks actually matter, and why buyers today look for manufacturers with strong mining control, modern processing setups, and reliable testing standards.

Synergy Chemical Industries, known for supplying consistent-quality limestone across India, often comes up in buyer evaluations, and by the end of this guide, you’ll understand the factors that make such manufacturers more dependable.

Why Limestone Quality Varies Widely in India

Variations in Mining Locations

Limestone deposits across India differ naturally in:

- CaCO₃ (calcium carbonate) percentage

- Magnesium content (MgO)

- Color and density

Regions such as Rajasthan and Gujarat are known for high-calcium limestone, while other zones may yield mixed-quality deposits. This is the core reason why buyers often receive inconsistent material.

Differences in Processing Standards

Not all factories follow the same crushing, screening, and sorting processes.

Issues often come from:

- Oversized or inconsistent particle sizes

- Moisture fluctuations

- Lack of screening equipment

These impact performance in kilns, chemical reactions, or cement formulations.

Certification Gaps

Many small suppliers operate without:

- ISO certification

- Dedicated lab testing

- Standardised batch control

This leads to unpredictable quality from load to load.

Key Factors to Evaluate in Limestone Manufacturers

Purity & Chemical Composition

The CaCO₃ percentage determines limestone suitability. High-calcium limestone (90–96% CaCO₃) is preferred for:

- Steel manufacturing

- Chemical production

- Water treatment

Lower grades may work for construction but not for industrial applications.

Density & Strength Indicators

For construction use, builders increasingly prefer high-density limestone due to its strength, durability, and better load-bearing capacity.

Mines & Production Capacity

Manufacturers with their own limestone mines and factories in India offer:

- Better control over sourcing

- More consistent material

- Stable pricing

Processing Facilities

A dependable manufacturer should have:

- Crushing plants

- Screening systems

- Dust control

- Quality labs

- Bulk loading capability

Certifications

Buyers increasingly ask for:

- ISO-certified limestone manufacturers

- Regular lab reports

- Third-party testing

These reduce the risk of rejected loads.

Types of Limestone Available in India

| Type of Limestone | Colour | CaCO₃ Purity | Best Applications |

| High-Calcium Limestone | White to off-white | 90–96% | Steel, chemicals, water treatment |

| Dolomitic Limestone | Greyish | Higher MgO | Agriculture, soil conditioning |

| Industrial/Construction Grade | Light grey | Standard Purity | Roads, buildings, general construction |

These limestone types available in India differ not only in purity but also in density, hardness, and usage suitability.

How to Choose the Best Limestone Manufacturer in India

Here’s a simple checklist buyers should use:

1. Ask for Mine Source

Where the limestone is mined directly influences purity.

2. Request CaCO₃ and MgO Test Reports

A genuine supplier shares batch-wise lab results.

3. Check Monthly Supply Capacity

Many buyers struggle because small suppliers cannot handle bulk orders.

4. Evaluate Transparency

Watch out for:

- Missing test reports

- Inconsistent samples

- Unknown mine locations

5. Ask for On-Site Testing

A quick field test or third-party inspection ensures you receive the correct grade.

Limestone Price in India per Ton

Limestone rates vary mainly due to:

1. Purity & Grade

Higher CaCO₃ content → Higher pricing.

2. Type of Limestone

White, high-density grades cost more than grey construction-grade stone.

3. Distance From Mine to Destination

Transport accounts for a major share of cost.

4. Bulk Orders vs Small Loads

Wholesale orders significantly reduce the limestone price in India per ton.

Benefits of Buying Limestone in Bulk

Bulk purchases offer advantages such as:

- Lower cost per ton

- Consistent quality for entire projects

- Stable monthly supply

- Reduced logistics hassle

This is especially important for industries searching for Limestone wholesale suppliers India or buyers wanting to Buy limestone in bulk in India.

Why Many Buyers Prefer Synergy Chemical Industries

Synergy Chemical Industries stands out due to:

In-House Mines

Direct control over raw material quality.

Advanced Processing Units

Crushing, screening, and modern handling systems ensure consistent sizing.

Strict Lab Testing & ISO Certification

Batch-wise analysis builds trust for chemical, steel, and water-treatment applications.

Pan-India Supply Capability

Strong logistics help meet large-scale industrial demand reliably. This section positions Synergy Chemical Industries naturally without salesy language.

Common Mistakes Buyers Make While Ordering Limestone

- Selecting suppliers based purely on the lowest price

- Skipping CaCO₃ and density testing

- Ignoring certifications

- Forgetting to ask for sample consistency

- Overlooking delivery capacity

Avoiding these saves time, money, and production delays.

FAQs

Q1. Who are the best limestone manufacturers in India?

Answer: Top manufacturers are those with their own mines, ISO certification, and strong processing facilities. Companies like Synergy Chemical Industries rank high due to consistent purity.

Q2. What should I check before ordering limestone?

Answer: Check CaCO₃ levels, density, mine location, monthly capacity, and certification.

Q3. What affects the limestone price in India per ton?

Answer: Purity, grade, transport distance, and bulk order size influence pricing.

Q4. Is high-density limestone better for construction?

Answer: Yes, it offers better strength and durability, making it suitable for load-bearing applications.

Q5. Are ISO-certified limestone manufacturers more reliable?

Answer: Yes. Certification ensures standardised processes, testing, and consistent quality.

Q6. What are the main limestone types available in India?

Answer: High-calcium, dolomitic, and construction-grade limestone.

Q7. Can I buy limestone in bulk directly from manufacturers?

Answer: Yes. Many industries prefer bulk orders due to cost benefits and stable supply.