Table of Content

- Understanding the Material Behind the Name

- Chemical Composition & Core Properties That Define Performance

- From Limestone to Lime Powder: How Hydrated Lime Is Produced

- Hydrated Lime vs Quicklime: What Industrial Buyers Must Know

- Where Hydrated Lime Powder Is Used Across Industries

- Why Industrial Buyers Prefer Hydrated Lime Powder

- Handling, Storage & Industrial Safety Considerations

- Choosing the Right Hydrated Lime Powder Supplier

- Frequently Asked Questions (FAQs)

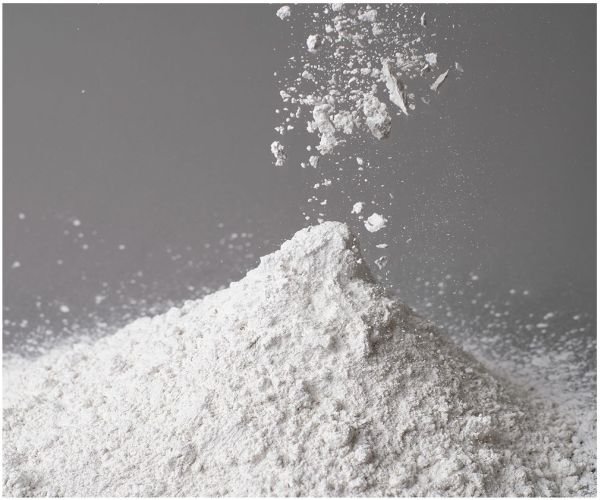

Hydrated lime powder, also known as calcium hydroxide powder, is a fine white alkaline material produced by hydrating quicklime with water. Industries prefer it because it is safer to handle than quicklime, chemically stable, and highly effective in applications like water treatment, construction, chemical manufacturing, and effluent control. Its ability to neutralize acids, control pH, and improve material strength makes it a dependable industrial input. Choosing an industrial grade hydrated lime powder supplier ensures consistent quality, purity, and performance across applications.

Understanding the Material Behind the Name

Why It’s Also Called Calcium Hydroxide Powder

Hydrated lime powder is the common industrial name for calcium hydroxide powder. Its chemical formula is:

Ca(OH)₂

This name matters because many industrial specifications, safety documents, and regulatory standards refer to the material by its chemical identity rather than its trade name.

In simple terms:

- Calcium (Ca) comes from limestone

- Hydroxide (OH) groups are added during hydration

- The result is a stable, alkaline compound suitable for controlled industrial use

How Hydrated Lime Differs from Natural Limestone

Although they come from the same source, limestone and hydrated lime are not the same material.

- Limestone is a naturally occurring calcium carbonate

- Hydrated lime powder is a processed, reactive product designed for industrial applications

Limestone is mainly used as a raw or structural material, while hydrated lime is used where chemical reaction, pH control, or binding properties are required.

Chemical Composition & Core Properties That Define Performance

Chemical Formula Explained Simply

The chemical composition of hydrated lime powder is calcium hydroxide (Ca(OH)₂). When it comes into contact with water, it releases hydroxide ions, which increase alkalinity. This is the key reason it is used in processes that require neutralization or pH adjustment.

Unlike more aggressive alkaline chemicals, hydrated lime offers controlled reactivity, which is why industries prefer it.

Key Physical & Chemical Properties

| Property | Description | Why It Matters in Industry |

| Alkalinity | High pH | Neutralizes acidic waste and solutions |

| Particle Size | Fine powder | Improves reaction efficiency |

| Solubility | Slightly soluble | Allows controlled chemical action |

| Stability | Non-volatile | Safe storage and transport |

| Appearance | White powder | Easy identification and dosing |

These hydrated lime powder properties make it reliable across multiple industrial environments.

From Limestone to Lime Powder: How Hydrated Lime Is Produced

Step-by-Step Lime Hydration Process

Understanding the hydrated lime powder manufacturing process helps buyers evaluate quality.

- Limestone Calcination

Limestone is heated in kilns to produce quicklime (calcium oxide). - Hydration

Quicklime is carefully reacted with water. This process, called the lime hydration process, produces hydrated lime powder. - Controlled Processing

Temperature, moisture, and reaction time are carefully managed to ensure consistent quality.

Why the Manufacturing Process Matters

Not all hydrated lime powders behave the same. The production process affects:

- Reactivity

- Particle size

- Moisture content

- Purity levels

For industrial use, consistency is critical. Poorly hydrated material can cause dosing issues, uneven reactions, or excess waste.

Quality Checks in Industrial Grade Hydrated Lime Powder

Industrial manufacturers test for:

- Chemical purity

- Residual moisture

- Particle distribution

- Compliance with industry standards

This is what differentiates industrial grade hydrated lime powder from lower-quality alternatives.

Hydrated Lime vs Quicklime – What Industrial Buyers Must Know

Key Differences Explained Clearly

| Factor | Hydrated Lime Powder | Quicklime |

| Chemical Form | Calcium hydroxide | Calcium oxide |

| Handling | Safer and easier | Highly reactive |

| Storage | Stable | Requires strict control |

| Industrial Use | Widely preferred | Limited and cautious |

Why Hydrated Lime Is Often the Safer Choice

While quicklime reacts aggressively with water, hydrated lime has already undergone hydration. This makes it:

- Easier to store

- Safer to transport

- More predictable in industrial applications

For most buyers, hydrated lime vs quicklime is a choice between safety and reactivity and hydrated lime wins in controlled environments.

Where Hydrated Lime Powder Is Used Across Industries

Hydrated Lime Powder for Water Treatment

One of the largest uses is in water and wastewater treatment.

It helps in:

- pH adjustment

- Water softening

- Removal of heavy metals

- Clarification processes

Because it offers controlled alkalinity, hydrated lime powder for water treatment is widely preferred by treatment plants.

Hydrated Lime Powder for Construction

In construction, hydrated lime improves:

- Workability of mortars

- Durability of plasters

- Flexibility in masonry

- Soil stabilization

It is commonly used in traditional as well as modern construction methods where long-term performance matters.

Hydrated Lime Powder Applications in Manufacturing

Manufacturing sectors use hydrated lime powder in:

- Chemical processing

- Sugar refining

- Paper and pulp production

- Effluent treatment plants

- Metal processing

These hydrated lime powder industrial uses depend on its chemical stability and predictable behavior.

Why Industrial Buyers Prefer Hydrated Lime Powder

Operational Benefits

Industrial buyers choose hydrated lime because:

- It is easier to dose accurately

- It reacts in a controlled manner

- It reduces equipment corrosion

- It improves process efficiency

These advantages reduce downtime and improve output quality.

Environmental & Regulatory Advantages

Hydrated lime supports:

- Compliance with wastewater discharge norms

- Reduction of acidic waste

- Cleaner industrial by-products

This is why it is considered safe for industrial use when handled correctly.

Handling, Storage & Industrial Safety Considerations

Safe Handling Practices

Although hydrated lime powder is safer than quicklime, basic precautions are essential:

- Use gloves and masks

- Avoid direct inhalation

- Minimize dust generation

Storage Guidelines

For best performance:

- Store in dry conditions

- Protect from moisture

- Use sealed bags or containers

Proper storage ensures consistent quality during application.

Choosing the Right Hydrated Lime Powder Supplier

What Industrial Buyers Should Look For

A reliable hydrated lime powder supplier should offer:

- Consistent quality

- Industrial-grade specifications

- Reliable supply chain

- Technical support

Role of Synergy Chemical Industries

Synergy Chemical Industries focuses on supplying high-quality hydrated lime powder for industrial applications. By emphasizing quality control, consistent manufacturing practices, and industry understanding, the company supports buyers who require dependable performance rather than just a commodity product.

Frequently Asked Questions

Q1. Is hydrated lime safe for industrial use?

Answer: Yes. When handled properly, hydrated lime powder is safe and widely used across industries due to its controlled reactivity.

Q2. How is hydrated lime powder different from limestone?

Answer: Limestone is a natural mineral, while hydrated lime powder is a processed chemical product designed for industrial reactions.

Q3. Can hydrated lime powder be used in water treatment plants?

Answer: Yes. It is commonly used for pH control, water softening, and contaminant removal.

Q4. What industries use hydrated lime powder the most?

Answer: Water treatment, construction, chemical manufacturing, paper, sugar, and metal processing industries.

Q5. How should hydrated lime powder be stored?

Answer: It should be stored in dry, moisture-free conditions in sealed packaging.

Q6. What does “industrial grade” hydrated lime mean?

Answer: It refers to hydrated lime that meets purity, consistency, and performance standards required for industrial applications.

Q7. How do I choose a reliable hydrated lime powder exporter?

Answer: Look for manufacturing consistency, quality certifications, and experience in handling bulk industrial supply.